Wire Preparation Services

Interstate Wire is committed to providing you with the most effective wire management solution for your application. In addition to carrying a full line of wire management products from the leading cable and wire product manufacturers, we offer extensive value-added services. Selecting the wire product and configuration that is best for your application is just the first step in purchasing your wire and cable product. The wire needs to be "finished" to meet the specific requirements for your application – whether it's a specific color or colors to identify the wire, a custom length to fit in your product or custom packaging to reduce storage costs and increase the efficiency of your production line.

Interstate Wire's wire preparation services provide you with production-ready wire, increasing the efficiency of your production line while reducing costs. Our goal is to provide you with a solution that meets your exact requirements, ensuring the highest quality end product.

The services we offer include the following:

Wire Identification Solutions

Wire and cable are often dyed specific colors to aid in identification of the wire for circuit control and to assist in inventory control. Agency standards limit the colors of wire to ten standard colors for easier identification and safe operation of equipment. To overcome this restriction, we use striping as a method to differentiate wires for custom applications and when more than ten circuits need to be identified.

- Dyeing – In order to dye a wire, we pass the wire through a dye reservoir using a system of pulleys. The wire is then pulled through a wiper and into a heat tower to dry and cure. The wire jacket absorbs the color, which is permanent and durable. Most PVC compounds can be dyed, with the exception of CV-cured or irradiated materials, as they are designed to repel the compounds found in the dyes. Custom colors are available.

- Striping – Striping is used for extruded wire and is produced by using a spinning striper head during the dyeing process. Interstate Wire can apply longitudinal or spiral stripes, with up to three spiral or two horizontal stripes, using custom color combinations to fit your requirements. Striping can be used for most PVC compounds, rubber, silicone and PTFE.

Wire Labeling Solutions

Wires are labeled to provide clear indicators of the purpose of the wire or to provide safety information about the wire. Many finished wires or cables include information about the wire, including model information, voltage and safety messages on the wire or cable. Labeling is commonly used for consumer products to ensure safe and correct use of the cable. Interstate Wire can print your custom message on your wire or cable product. Printing is available for cut and uncut wire. We offer inkjet printing and marking.

Wire Installation Solutions

Prepared wire and cable can increase the efficiency of your production line. It provides you with wire that is ready to install without requiring any additional work during production. This can include twisted or paired wires so that production workers do not have to configure the wire prior to installation and cut and stripped wire to allow for easy attachment to the product.

- Twisting – Wire twisting groups single or multi-conductor cables into the arrangement you need for your application. Twisting services provide a consistent product that holds its configuration during processing and cutting and, by reducing handling on the production floor, reduces the potential for contamination of the wire during production. Interstate Wire offers twisting for many sizes, color combinations, twists per foot and type of material. We have the capability for gauge sizes from 40AWG through 8AWG, with larger sizes available upon request.

- Cutting and Stripping – Custom lengths and stripped ends ensure that the wire and cable for your product meet the exact requirements of your application and are ready for installation. The cut wire and stripped ends are consistent and exact, reducing problems and eliminating waste. Interstate Wire has the capabilities to cut wire to specified lengths, strip the insulation at one or both ends and package the wire. We also offer tinning for cut and stripped wire.

Wire Packaging Solutions

Packaging your wire so that it is easily stored and ready to be used during production can provide substantial savings in inventory and production costs. Whether you are working with uncut or cut cable and wire, Interstate can provide you with a packaging solution for your wire and cable.

- Reels and Spools – Most uncut wire is stored using a cardboard or pressed paper spool, or drum. The wire is wound around the spool, providing safe storage as well as easy removal of the wire when it is needed. These reels of wire can hold thousands of feet of wire, and can be used with production machinery. They are available in many sizes and configurations and Interstate Wire offers custom spools to meet your production and equipment requirements. We can provide wood, plastic or metal reels and spools and offer cutting and re-spooling services.

- Custom Kitting – Many prepared wire products require special packaging. Cut wires or combinations of wires and cables that need to be packaged for easy access in production, or cables that are packaged for end users are some examples of products that require special packaging. Interstate Wire has the capabilities to package these products to meet your production or end user requirements.

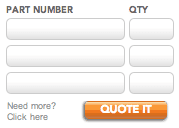

As the premier distributor of wire and cable products, Interstate Wire offers the highest quality products available for your wire and cable applications. Our value-added wire preparation services will provide you with the most effective solutions for your applications, ensuring efficient production and a high quality end product for your customers. Contact us today!